Air Suspension 101

Air Suspension Basics

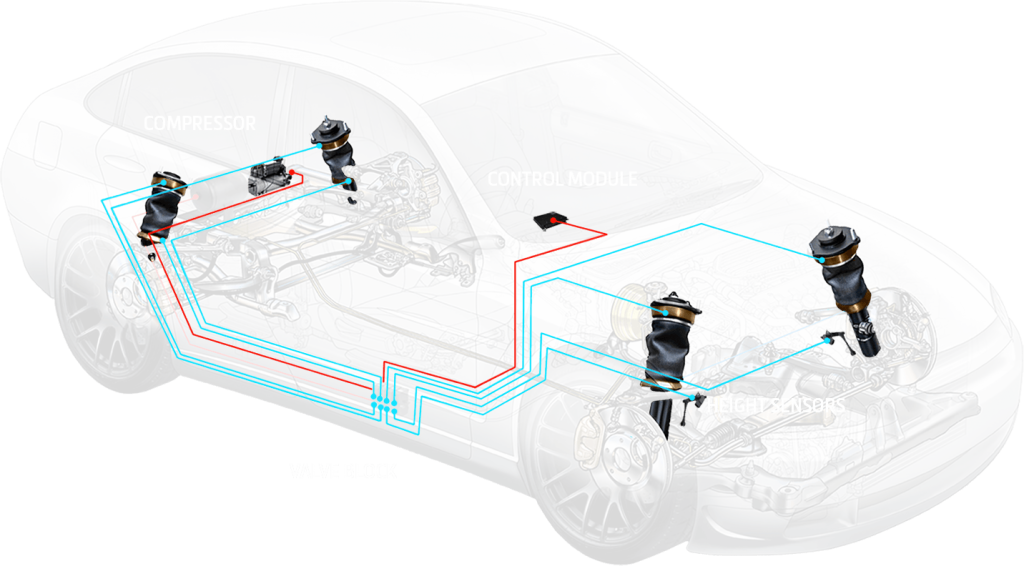

Air suspension is an alternative to traditional coiled steel springs for luxury vehicles. An air suspension system is made up of a handful of key components that are broken down below. With this setup, vehicles will have auto-leveling functions, added safety and a smoother, more consistent ride.

Air Suspension Components

The air suspension compressor pumps dried air towards the valve block.

The solenoid valve block is distributes air into the air suspension system.

Air springs use the compressive abilities of air and heavy-duty rubber to absorb vibrations and raise or lower the vehicle.

Air Struts combine a shock with an air spring to provide structural support for the car’s suspension.

The control module manages the vehicle’s air suspension system. It communicates with the valve block to optimize ride comfort, safety and auto-leveling.

Height sensors determine the proper ride height of the vehicle. They send instructions to the control module until the vehicle is at the correct height.

We live by one simple premise: do one thing and do it better than anyone else.

Arnott is the authority in replacement air suspension systems. We have an ongoing commitment to world-class development, manufacturing and testing. With this, we set the industry standards for quality and performance in both new and remanufactured air suspension products.

Arnott leads the way in remanufactured replacement air suspension products. All components, both new and restored, are rigorously tested before they leave our facility. This commitment to R&D, manufacturing and quality gives us the confidence that every single Arnott product is designed to perform and built to last.